From truck to tractor: Be prepared for winter

The trucking industry is going through many changes, and diesel fuels are often left out of the conversation. There are, however, important considerations to take into account when thinking about diesel fuel. The right fuel, with the right additives, from the right supplier can improve performance, reduce maintenance costs, introduce efficiencies and improve your bottom line.

Winter is coming. As temperatures begin to drop, you may be wondering what you can do now to prepare your diesel vehicles and equipment for what’s ahead and avoid breakdowns. Proper maintenance, especially before extreme weather, is critical to the operability of your vehicles and equipment, and part of that care is fuel selection. Here are a few tips and tricks to help you prepare your vehicle for the wintery conditions ahead, including making the right fuel choice.

- Check all electrical components and materials — especially batteries — to ensure proper functionality. Batteries have to work harder than usual to start vehicles in cold temperatures, and there aren’t always warning signs before the battery fails. To help prevent this, drivers need to make sure the battery cables are tight and free of corrosion and proactively get the battery tested before the cold temperatures arrive, especially if the battery is more than 3 years old.

- Accessorize appropriately — with windshield wiper blades specific for winter conditions. It’s also critical during the winter to regularly “top-off” washer fluid with fluid that’s formulated for winter conditions, ideally the -20°F fluids. In heavy snowfall areas like Montana, winter or snow tires can also be a worthy investment for safety. Winter tire compounds resist hardening at low temperatures and provide a significant upgrade in cold weather grip and braking compared to summer or all-season rubber.

- Conduct routine maintenance throughout the winter — including washing the entire vehicle, which will protect the paint as well as remove road salt and prevent corrosion under sediment that can wear through the protective coatings. It’s also important to regularly check the air pressure in the tires, because cold temperatures can decrease the air pressure, which can adversely impact tire wear and vehicle handling.

- Request pre-blended winterized diesel fuel from your Mobil Branded Reseller — such as Mobil Diesel Efficient™. It will help commercial vehicles/equipment remain fully operational in low temperatures. Understanding the science behind diesel fuel and the impact of cold weather is key to taking the best possible care of diesel vehicles during the extreme cold.

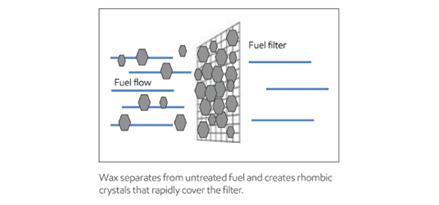

Diesel fuel is impacted by ambient temperatures, so its performance characteristics need to be managed throughout the year to ensure proper equipment and engine operation — especially in cold environments. In cold climates, winterized fuel such as Mobil Diesel Efficient™ can help reduce occurrences of fuel gelling — which can cause fuel starvation, loss of engine power and stalling.

Pre-additized winter diesel fuel means the cold flow improver (winter technology) is injected into the fuel at the terminal to help ensure precise consistency, quality and performance as it enters fuel tanks. Purchasing diesel fuel that is already additized for winter conditions is also preferable to using aftermarket cold flow additives, as the additives need to be added at the right temperatures, in the right concentration, and mixed in so that they are fully dissolved. If not added properly the benefits of cold flow additives may not be realized, and in extreme cases could cause operational issues. Winterized diesel is also beneficial for those in the agriculture industry.

Considerations for storing farm equipment for the winterIt’s important to follow your equipment manufacturer’s operator manual, but here are some additional tips before storing your equipment.

- Check the fluids — to help prevent engine corrosion in storage, change the oil and filters, and top off the fuel tank to reduce moisture accumulation due to condensation.

- Clean the equipment — help prevent pests from making a home in your equipment by cleaning out the leftover bits of seed and other food, and remove dirt and dust to prolong the equipment life and help prevent corrosion.

- Make repairs now — ensure your equipment is ready for spring by making necessary repairs.

- Find it a good home — if possible, store the equipment indoors, and if not, make sure to cover it properly.